CONTATTI

INDIRIZZO

SOCIAL

Via di Badia, 17

51100 Pistoia (PT)

Italia

LPMeccanica

P.IVA 02106520477

THE COMPANY

The company was born from many years of experience in the field of mechanical design, machine construction and product industrialization. The work carried out aims to provide a high-quality technical contribution starting from the specific needs requested. Since the preliminary design, particular attention is paid to identifying the right balance between the sustainability of the final product and the quality level of the product itself: this work is developed through an iteration between mechanical design and production cost analysis. The main objective is to guarantee an effective, simple and fast technical contribution, placing multidisciplinary technical skills at the customer's service.

OUR SERVICES

PRELIMINARY DESIGN ANALYSIS

The specific service and product needs, project requirements, operating conditions, and timing requirements are analyzed. All project inputs are taken into account in order to verify feasibility, identify various solutions and the costs related to achieving the final goal. Together with the customer, the main components of the system and the methods of use are identified.

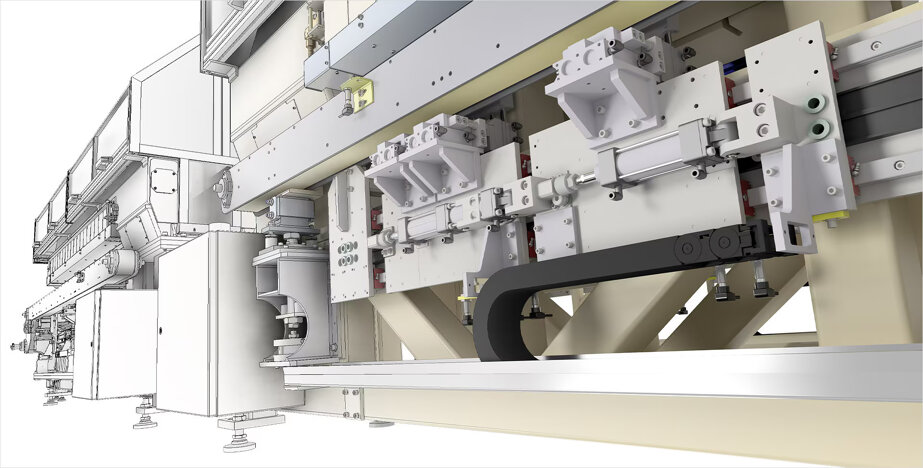

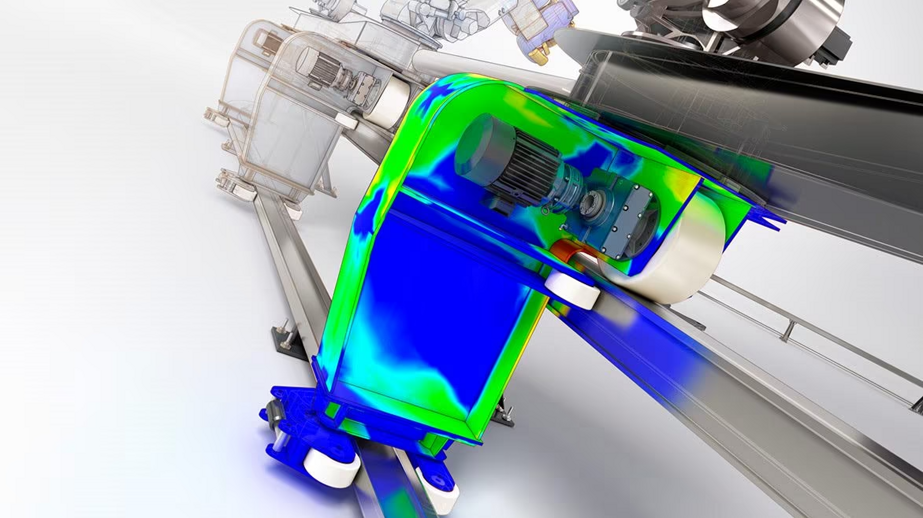

3D MODELING

Three-dimensional modeling of the product and system is the first step of the project. In this phase, the system components are modeled, both custom-made products (e.g. mechanical or carpentry components) and products already on the market (e.g. commercial components). Three-dimensional modeling is developed together with structural analyses and regulatory requirements, where required.

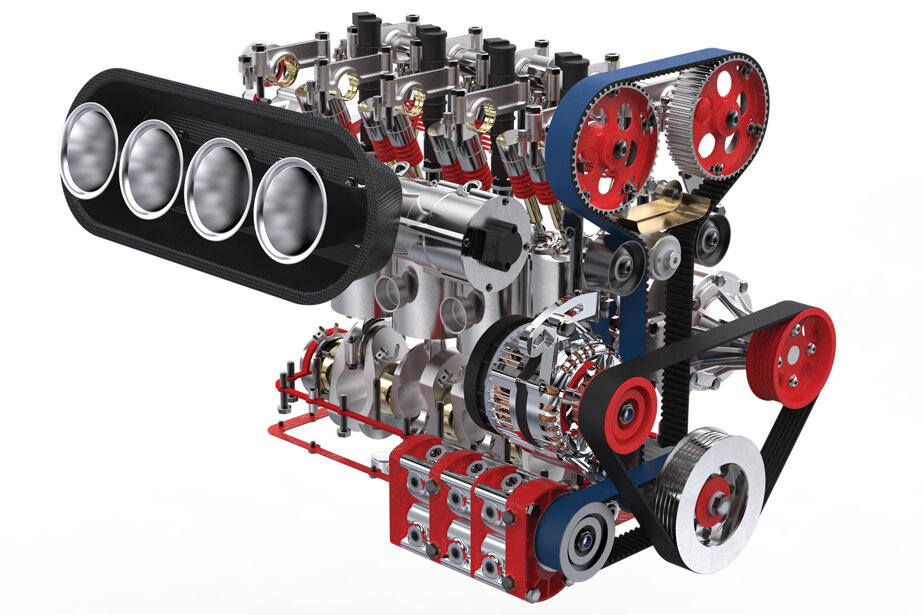

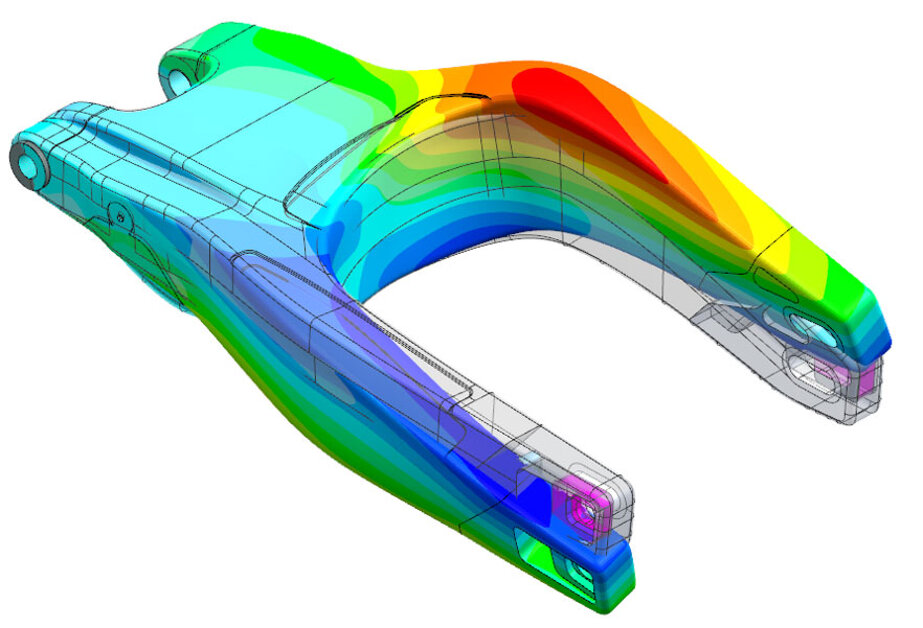

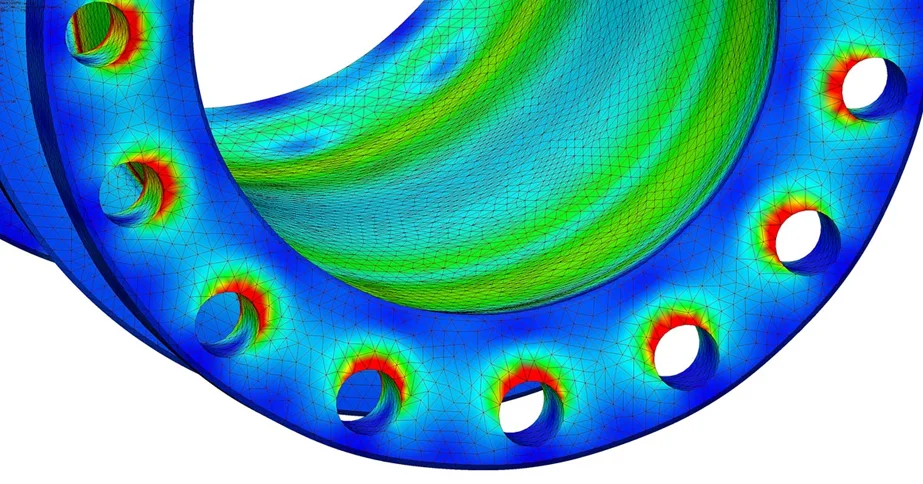

STRUCTURAL ANALYSIS

The system components are structurally verified, considering the load conditions (static, fatigue, dynamic stresses) and the operating conditions (e.g. temperature, pressure, humidity, corrosion conditions, wear conditions). The verification satisfaction criteria are dictated by the dedicated standards.

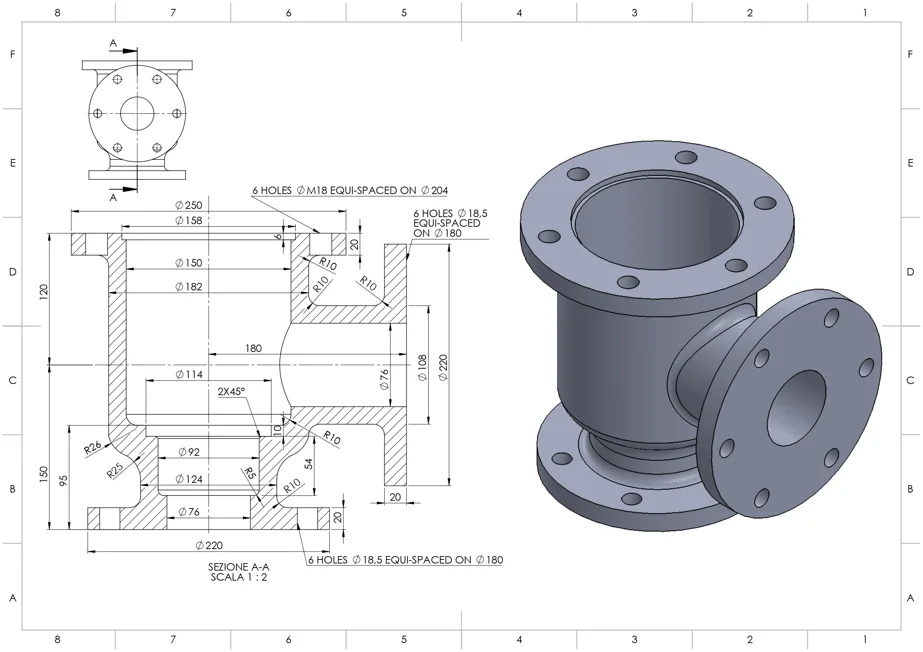

DRAWING

The project is finalized in the technical construction drawings, where all the information relating to the construction and procurement of materials is reported (dimensional drawings, tolerances, material and related characteristics, treatment, surface protection, commercial codes). The system and the components that constitute it are listed in the bill of materials.

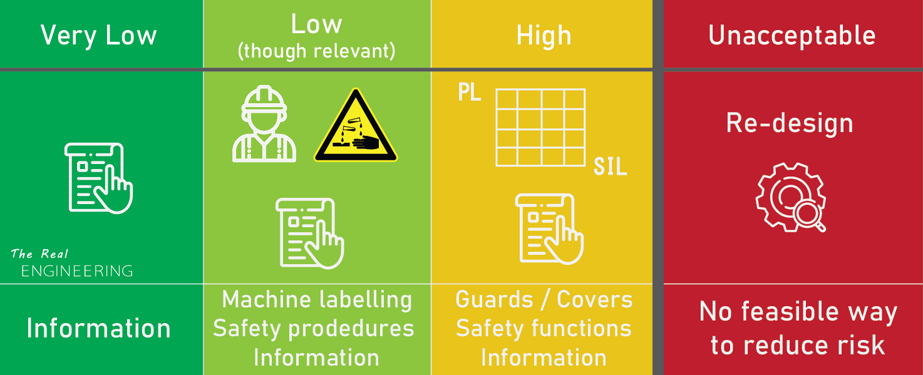

CE MARKING

Analysis of product conformity with the reference directives and standards (e.g. Machinery Directive, PED, ATEX). Preparation of the product Technical File, including the documentation of conformity to the specific Directive (Risk Analysis, Structural Checks, Use and Maintenance Manual).

PROTOTIPATION AND SUPPORT TO PRUDUCTION

From design to product: support in the construction and testing phase of prototyping, analysis of results, identification of any critical issues and resolution interventions. Support for type approval and product industrialization: together with the customer, the processes and equipment necessary for series production are identified, in order to maximize the company's productivity.

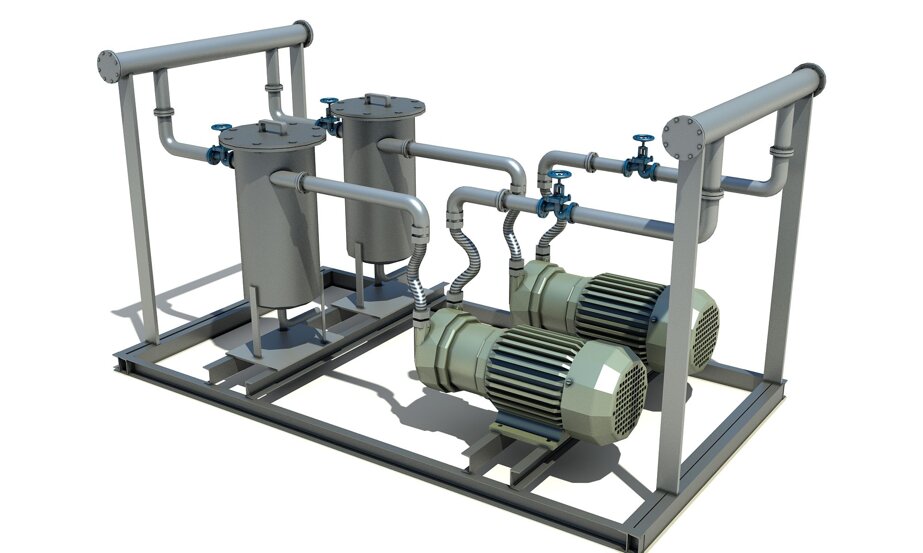

HARDWARE CONSTRUCTION

Construction of machines and equipment in the following fields:

- Metal carpentry and mechanical processing structures.

- Manual or automatic industrial machines for the handling, analysis or specific processing of the product.

- Manual or automatic test benches for testing or tests of various types (e.g. fatigue tests).

CONTACTS

ADRESS

SOCIAL

Via di Badia, 17

51100 Pistoia (PT)

Italia

LPMeccanica

VAT N. IT02106520477